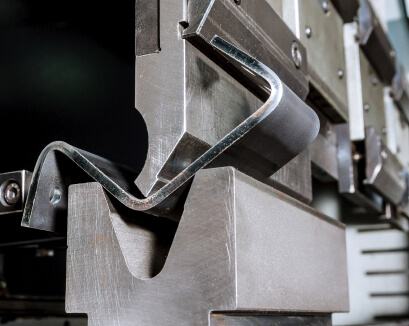

Alloy Steel for Metal Forming & Bending

FLEXOR® is a proprietary alloy steel for metal forming and bending developed by Pennsylvania Steel Corporation. Unlike standard alloy steels or tool steels, FLEXOR® is engineered with a unique chemistry that offers exceptional hardness, machinability, and wear resistance. This steel has become a trusted choice for industries requiring high-strength, durable materials that withstand demanding metal forming processes.

FLEXOR® is highly versatile in heat treatment, allowing manufacturers to achieve a wide range of physical properties, including:

- Higher core hardness – Ensures uniform strength across the cross-section

- Superior machinability – Especially at higher hardness levels

- Dual properties when case hardened – Combining surface hardness & core toughness

Its fine-grain microstructure enhances fatigue and tensile strength, making FLEXOR® an ideal solution for precision forming, machining, and bending applications in metalworking, oil & gas, and advanced manufacturing.

FLEXOR® Alloy Composition

- Chromium (0.85%) – Enhances hardness & wear resistance

- Molybdenum (0.5%) – Improves toughness & high-temperature strength

- Tungsten (0.5%) – Provides abrasion resistance

- Carbon (0.34%) – Strengthens the steel matrix

- Nickel (0.1%) – Enhances ductility

- Manganese (0.8%) – Improves toughness

- Silicon (0.3%) – Increases hardenability

- Sulfur (0.015%) – Aids machinability

FLEXOR® is the only CrMoW steel readily available for oil & gas, precision metal forming, and high-performance machining. Its dense material structure and thermal conductivity provide superior fatigue and impact resistance, making it well-suited for mud motor drive shafts, hydraulic shafts, mandrels, drilling bits, and downhole tools.

Industry Applications – Metal Forming & More

FLEXOR® is a preferred material in metal forming & bending due to its strength, toughness, and wear resistance. It is used in:

- Metal Forming Dies & Tooling

- Bottom Hole Assembly Tooling

- Bearing Adapters

- Collets & Chuck Jaws

- Cutter Bodies & Chuck Bodies

- Diaphragm Chucks

- Drive Conveyors & Dynamometer Forks

- Gears, Hydraulic Shafts & Pump Shafts

- Induction Hardened Shafting & Mandrels

- Quill Blocks, Rams & Spindles

- Stub Shafts, Tool Holders & Wear Strips

Its high-strength and wear-resistant properties extend component lifespan, reduce maintenance costs, and improve manufacturing performance across industries.

Why FLEXOR® Outperforms Other Alloy Steels

FLEXOR® has a proven track record in high-performance metal forming applications, consistently matching or surpassing traditional alloy steels like 4330V mod, 4140, and 4340.

Advantages Over Conventional Alloy Steels

- Higher core hardness – Delivers greater fatigue & tensile strength

- Better machinability – Even at higher hardness levels

- Superior wear resistance – Ideal for high-impact applications

- Enhanced heat treatment flexibility – Allows for customized performance

- Reliable consistency – Ensures minimal deviation across production batches

For manufacturers in metal forming, oil & gas, and precision machining, FLEXOR® provides unmatched performance, reducing downtime, lowering costs, and improving efficiency.

Optimize Your Metal Forming Process with FLEXOR®

Pennsylvania Steel Corporation’s FLEXOR® alloy steel for metal forming and bending is designed for precision, strength, and durability. Its exceptional properties make it the go-to material for forming, machining, and high-performance manufacturing applications.

Let’s discuss how FLEXOR® can improve your metal forming operations today!

Testimonials

"At Powerhold we use FLEXOR® exclusively on all our special design work-holding Diaphragms. The performance and machining quality of FLEXOR® is superior to anything we have utilized in the past.

Today’s customer demands a quality product that performs consistently...FLEXOR® enables us to meet that goal every day."