9310 Alloy Steel

Pennsylvania Steel Corporation offers an alternative to SAE 9310 alloy steel.

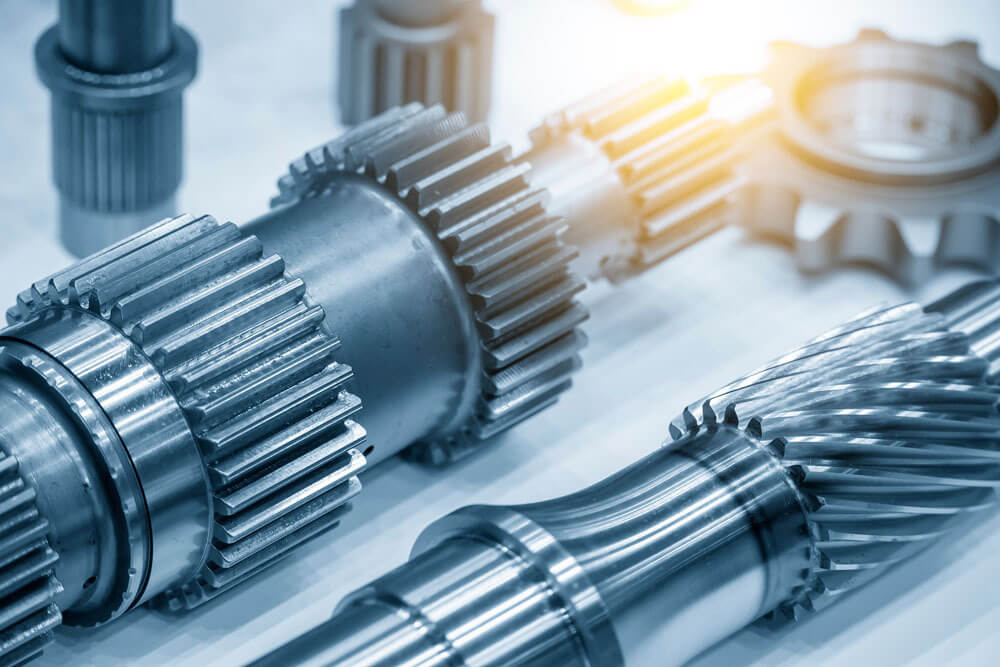

We produce FLEXOR® steel to provide similar, if not superior, chemical and mechanical properties to 9310 alloy steel. As a result, it can be used for many of the same applications as 9310 steel. These include applications that require high core strength, durability and fatigue resistance such as Aircraft and Aerospace Components, Automotive Components, Motor Components and Cutting Tools.

Being a proprietary grade, Pennsylvania Steel ensures that all FLEXOR® heats meet a high quality vacuum degas electric arc furnace melt process in order to ensure cleanliness, grain refinement and maximum reduction ratios.

SAE 9310 Steel Chemistry Composition vs. FLEXOR®

| Alloy | 9310 | FLEXOR® |

|---|---|---|

| Carbon, C | .07-.13 | .32-.36 |

|

Manganese, Mn |

.40-.70 | .60-.80 |

|

Phosphorous, P |

.02(max) | .025(max) |

|

Sulfur, S |

.02(max) | .025(max) |

|

Silicon, Si |

.15-.35 | .15-.30 |

|

Chromium, Cr |

1.00-1.40 | .75-1.00 |

|

Molybdenum, Mo |

.08-.15 | .40-.60 |

|

Tungsten, W |

- | .40-.70 |

FLEXOR® Properties

FLEXOR®'s dependable quality and adaptability in heat treatment allows for a wide range of physical properties that are more appealing than those of typical ASTM, AISI or SAE 9310 alloy steel.

FLEXOR® has a higher core hardness, resulting in a more uniform hardness through any cross section. The more uniform hardness and a fine grain microstructure produce a steel that exhibits superior fatigue and tensile strength, high wear and abrasion resistance and is an excellent material for complex shapes and sectioned parts.

FLEXOR® Sizes & Conditions

FLEXOR® steel is available in a variety of sizes and conditions. These include, but are not limited to:

- Decarb free alloys

- Hot rolled flats

- Hot rolled rounds

- Hot rolled plates

- Peeled steel bars

- Turned forged rounds and billet

- Ground and polished rounds

Contact Pennsylvania Steel Corporation today to learn more about FLEXOR® and its advantages over 9310 alloy steel.

Testimonials

"At Powerhold we use FLEXOR® exclusively on all our special design work-holding Diaphragms. The performance and machining quality of FLEXOR® is superior to anything we have utilized in the past.

Today’s customer demands a quality product that performs consistently...FLEXOR® enables us to meet that goal every day."

Testimonials

"Just wanted to take a minute to say thanks. I always receive my orders on time and without any complications. I appreciate you keeping me so up to date on the order process through email, and the way the steel is cut and packaged so carefully. Using your Product (FLEXOR®) has increased standard tool life by as much as 25%-30%. Thank you again for all you hard work. I look forward to business with you again and again, it's always a pleasure!"

Testimonials

"Pennyslvania Steel Corporation has been a valued supplier for our company going on two decades. FLEXOR®'S versatility and reliability have been extremely helpful to the products we manufacture. Due to to FLEXOR®'S versatility at various hardness' we are able to use it at 28-32 HRC, 28-32 HRC and nitrided, or through hardened anywhere between 42 and 50 HRC. In our experience FLEXOR® has superior machinability to other comparable steel grades especially in higher hardness'. We machine FLEXOR® at 40 HRC and find this to be a key benefit to our manufacturing process."