Case Studies

FLEXOR® Outperforms 4330V

In recent tests FLEXOR® has been compared to 4330V for high torsional loading and wear resistance in the Oil and Gas Drilling Industry. FLEXOR® has proven to have high toughness even in elevated hardness (40+HRC).

In a typical mud motor, previous drive shafts were known to have abrupt failures causing down and additional tooling issues. The FLEXOR® drive shaft bent and kept performing until it was discovered on a routine maintenance evaluation.

- FLEXOR® had a higher toughness (even in elevated hardness

- FLEXOR® had the longer performance

FLEXOR® Used as an Alternative to 300M and 9310

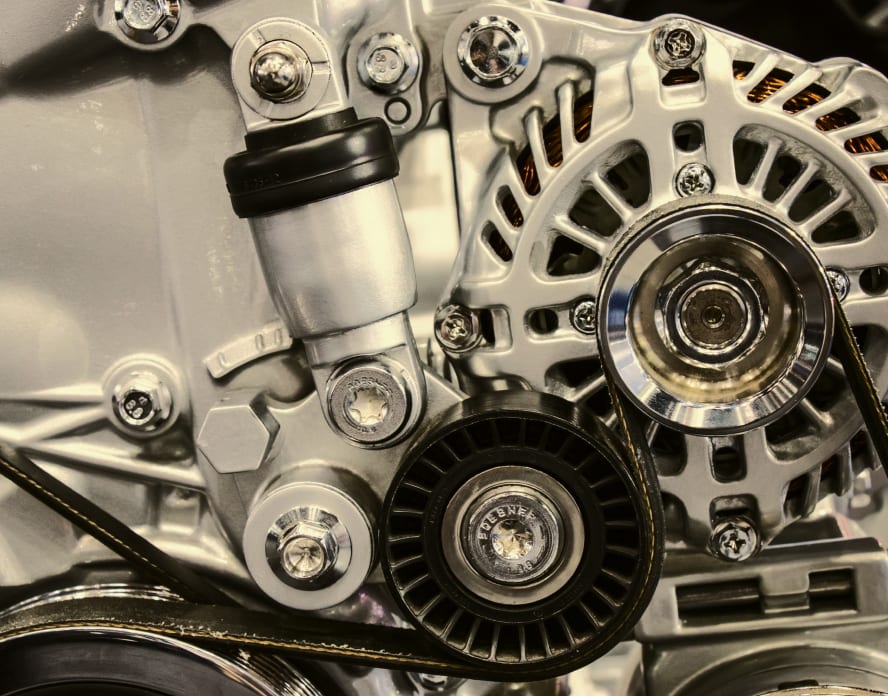

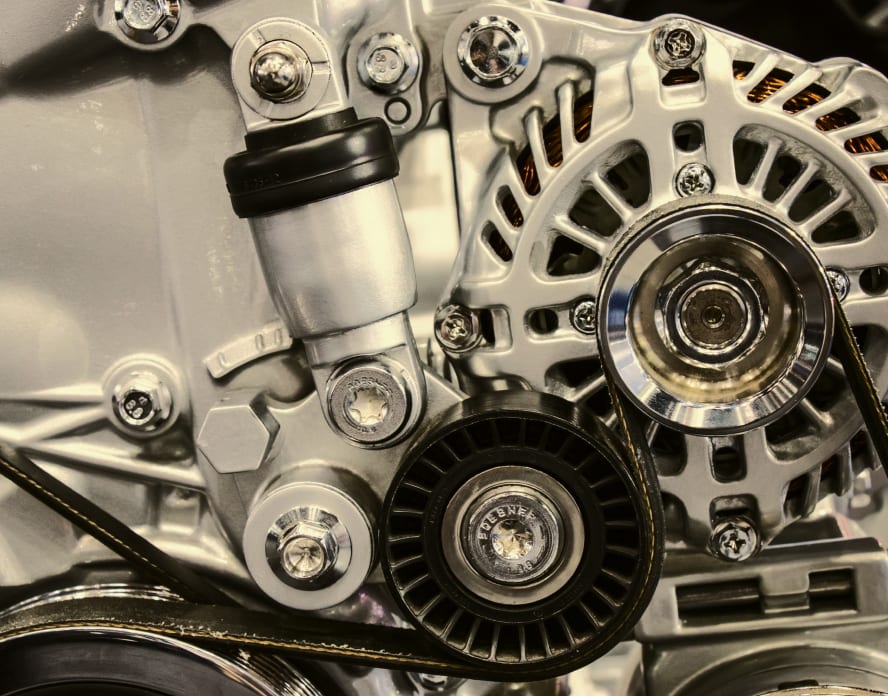

The Performance Racing Industry is finding FLEXOR® to be an excellent alternative to other higher alloy, more costly alloys such as 300M and 9310. FLEXOR® has been used in transmission components by many well known manufacturers where toughness and strength are paramount.

FLEXOR® Withstands Heavy Loads and Wear Resistance

In the closed die forging business a tough supportive wear resistant bolster is required to support the millions of cycles and excessive cyclic tonnage loads. FLEXOR® has been unsurpassed in the carburized condition at withstanding heavy loads and wear resistance.