About Pennsylvania Steel

Pennsylvania Steel's mission is to continually evolve into a smarter organization that is a world class manufacturer with superior products and services driven by a supportive work culture. Which encourages people to innovate, problem solve, excel and continually improve every aspect of the business. Pennsylvania Steel, a ISO 9001:2008 Certified company, has chosen to innovate in areas of product and service. Pennsylvania Steel is proud to continually build upon its 60 years of metallurgical expertise, service and problem solving to over 25 industries worldwide.

FLEXOR® Outperforms 4330V

In recent tests FLEXOR® has been compared to 4330V for high torsional loading and wear resistance in the Oil and Gas Drilling Industry. FLEXOR® has proven to have high toughness even in elevated hardness (40+HRC).

In a typical mud motor, previous drive shafts were known to have abrupt failures causing down and additional tooling issues. The FLEXOR® drive shaft bent and kept performing until it was discovered on a routine maintenance evaluation.

- FLEXOR® had a higher toughness (even in elevated hardness

- FLEXOR® had the longer performance

FLEXOR® Used as an Alternative to 300M and 9310

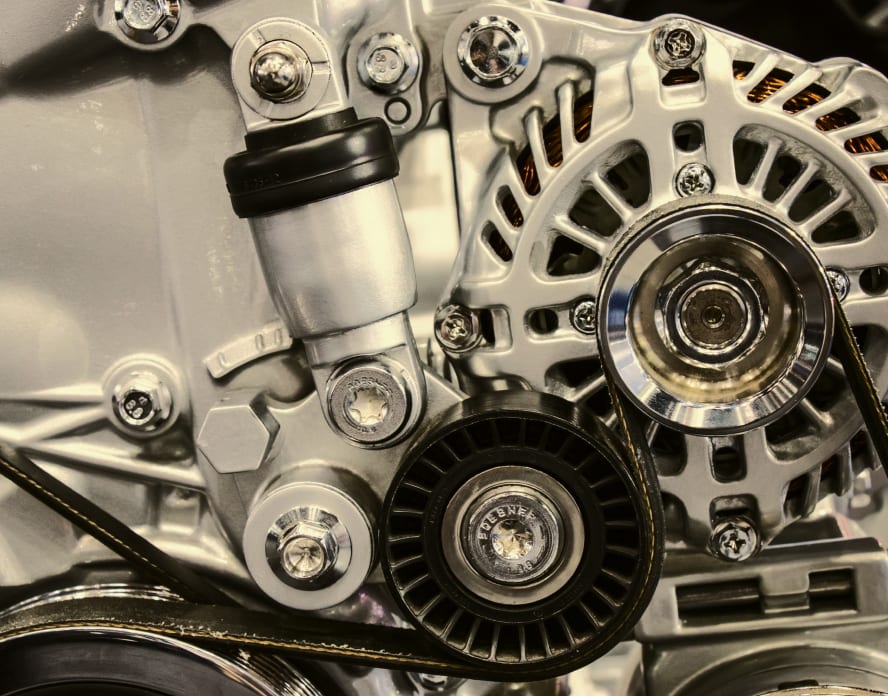

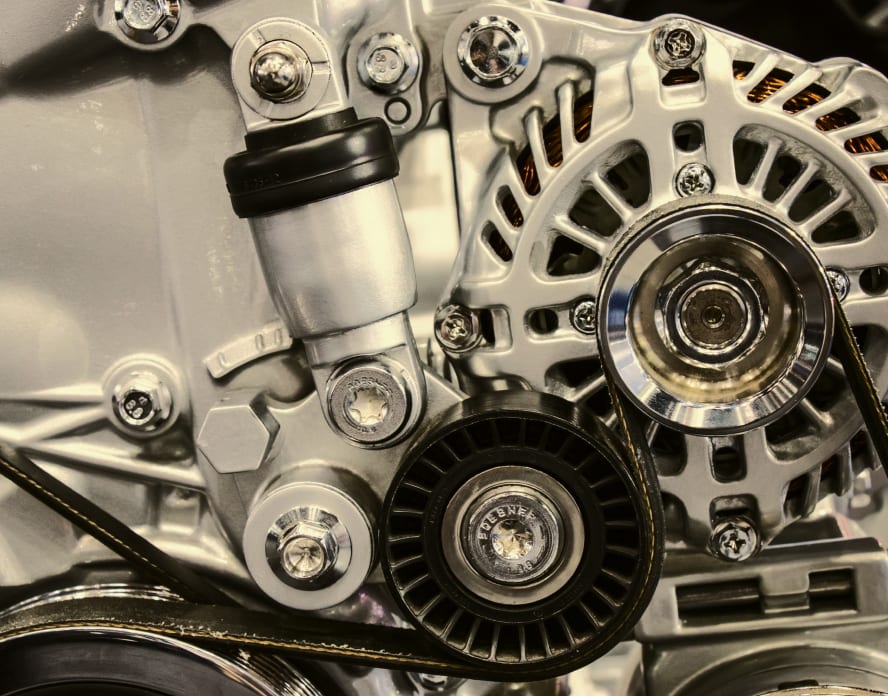

The Performance Racing Industry is finding FLEXOR® to be an excellent alternative to other higher alloy, more costly alloys such as 300M and 9310. FLEXOR® has been used in transmission components by many well known manufacturers where toughness and strength are paramount.

FLEXOR® Withstands Heavy Loads and Wear Resistance

In the closed die forging business a tough supportive wear resistant bolster is required to support the millions of cycles and excessive cyclic tonnage loads. FLEXOR® has been unsurpassed in the carburized condition at withstanding heavy loads and wear resistance.